Linear Motor

We´ve successfully commissioned the linear motor inside of our goTube research infrastructure together with engineers from Nevomo!

The cabling and installations in the tube are now complete, allowing us to test operational procedures of CargoTube and conduct various experiments with the propulsion system in combination with vehicle dynamics.

The first test runs with the linear motor are impressive! We´ve already achieved initial results that have exceeded our expectations.

The integration and testing of the linear motor is an important step in the development of CargoTube and hyperloop technology.

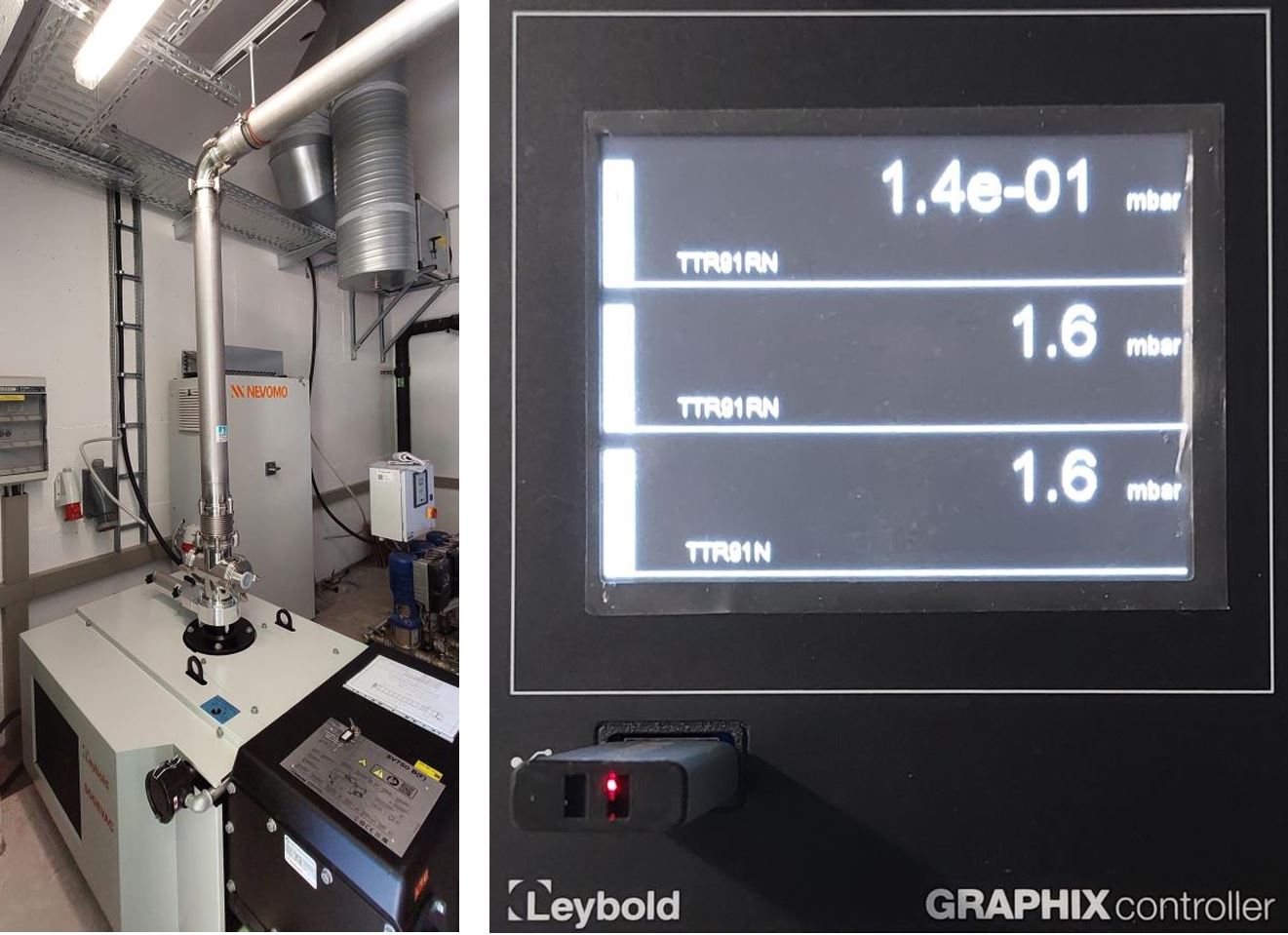

Vacuum Test

With the installation of our vacuum pump and the successful completion of our first vacuum test, we are thrilled to announce that we are now ready to commence low pressure operations!

Our vacuum tests have shown positive results, and we achieved an impressive pressure of 10 mbar in just 8 minutes! We can go even further, reaching a final pressure as low as 0.1 mbar.

The vacuum chamber is completely pressure tight, exhibiting a negligible leakage rate!

Vacuum Pump

The vacuum pump has been installed and the initial pump down tests from the last weeks have been successfully completed. Our pump system from Leybold is designed to evacuate the goTube facility rapidly, allowing for quick test cycles. This is important for the scientific experiments that are carried out in the test infrastructure. We are very appreciative towards our partner Leybold who have been working with us in designing and adapting the solution to our needs!

Now we are in the process of further vacuum test, showing us where special attention is needed when constructing a real world hyperloop system.

Next up is the completion of the electrical infrastructure for goTube including high-voltage connections to the inside of the tube to enable various experiments and the testing of the linear motor.

Equipment

Our team has started installing the solar modules. Solar cells are mounted above the tube to visualize the fully regenerative power supply of hyperloop systems. The modules will be an additional step towards an energy-efficient transport mode. The environmentally friendly option compared to air travel and the perfect complement to a fully electrified rail network for future sustainable mobility.

Would you like to play an active role in shaping the future during your studies?

As part of our working group, you can actively contribute with your ideas, work on innovative projects and participate in the development of pioneering technologies. Together, we are working on rethinking mobility and mastering the exciting challenges of the future. The journey has only just begun – we are looking forward to the milestones that are yet to come!

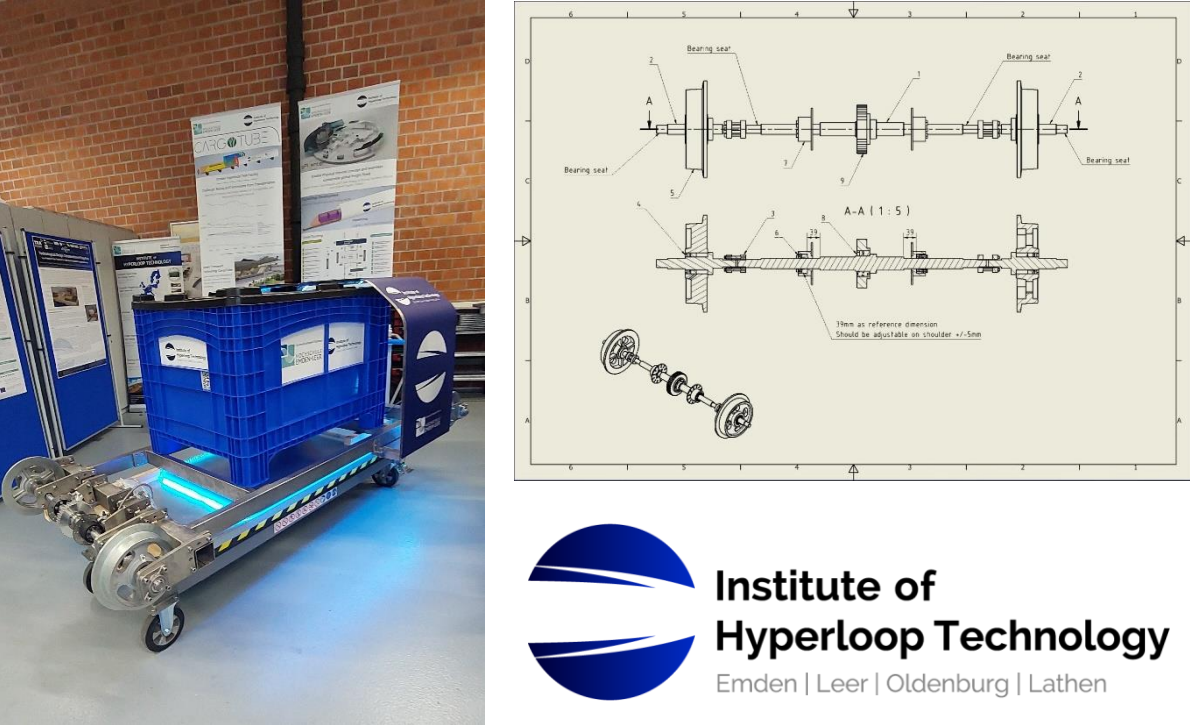

Equipment

One vehicle, many applications: this is probably the best way to describe our prototype.

The vehicle, which is currently under development, will not only transport various load carriers in our goTube in the near future, but various drive options will also be tested and evaluated in the low pressure environment, including the linear motor drive from Nevomo.

For this purpose, the prototype has a modular design so that drive elements can be exchanged quickly and the cargo hold adapted accordingly.

In addition, mechanical vehicle and electronic components can be tested in the tube environment as well.

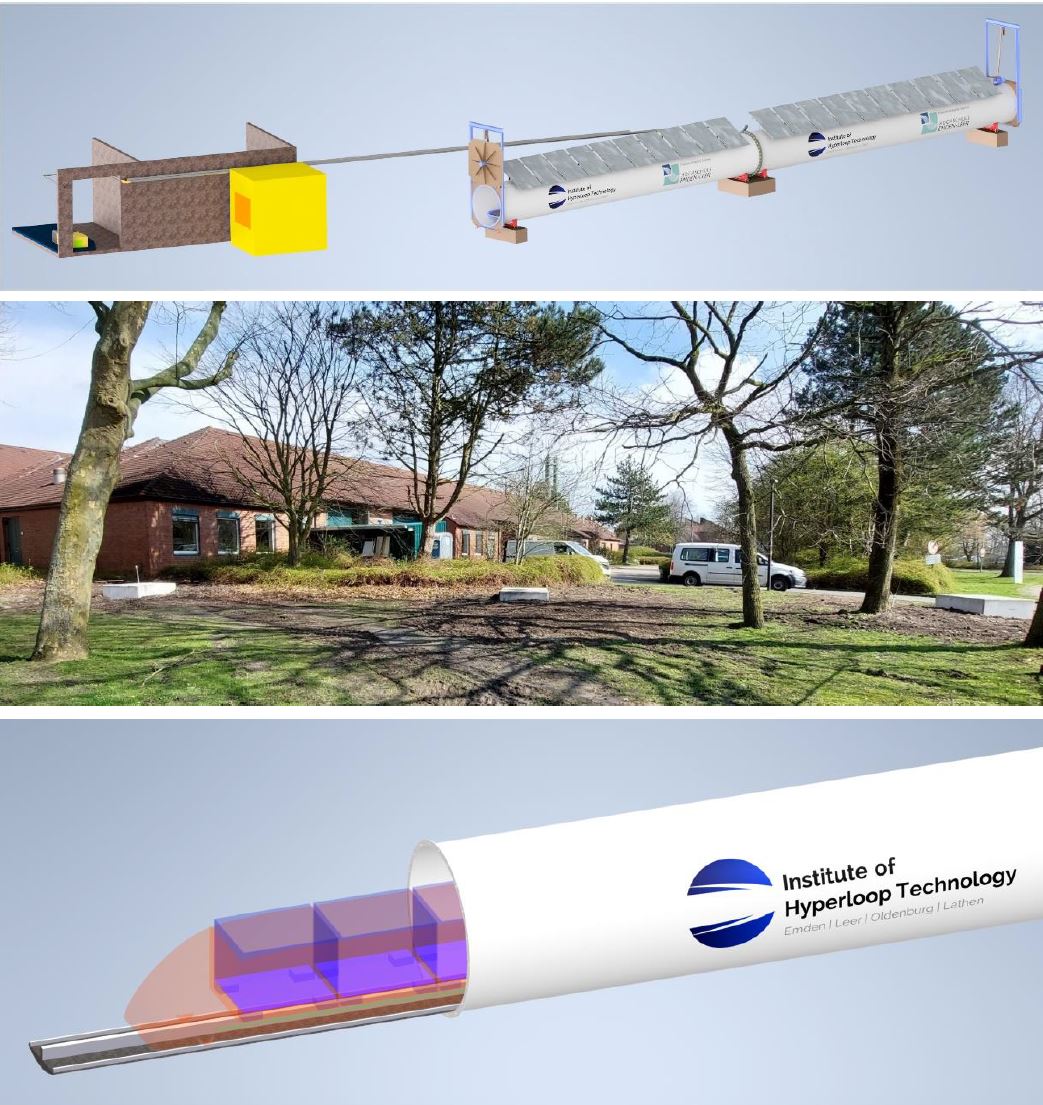

Installation

The next step has been taken: The installation of the linear motor in the goTube is progressing rapidly.

In the near future, electrification and commissioning will take place in cooperation with engineers from Nevomo. We will also install the solar modules and then further tests for integration will follow.

Installation

Another very important milestone in the completion of the goTube test facility has been reached! The Hyperloop tube was delieferd directly to its final destination outside of the FabLab at the University of Applied Sciences Emden/Leer. The technical installation will be prepared and carried out at the university over the next few weeks.

The 27m long tube will now be equipped with e.g. electronics, vacuum and propulsion systems. Afterwards the test infrastructure will be used to test various propulsion systems, the thermal behavior of systems in al low-pressure enviroment, and to determine operating sequences.

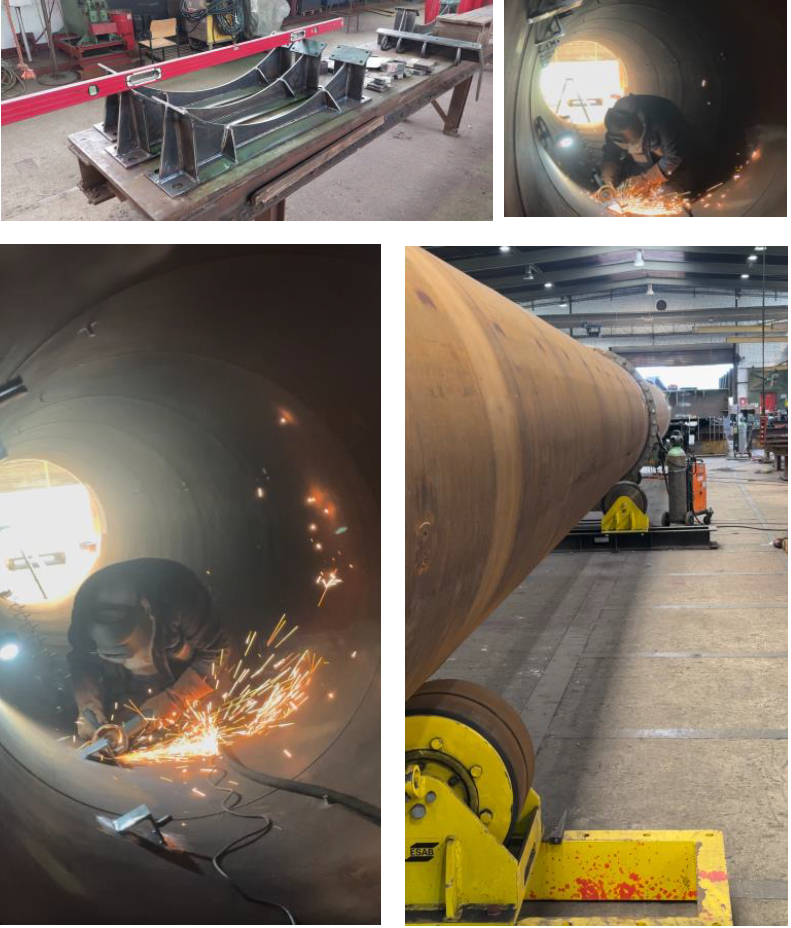

Conservation

We are looking at the final processes before the tube can be installed at its final location on our University of Applied Sciences grounds. The conservation is one of the last processes, which brings paint to the tube and ensures there won’t be any damage from the weather conditions here in East Frisia.

We are looking forward to welcoming the tube segments here in Emden at the campus very shortly!

Welding

At the site of our contractor, where the pipes arrived from our supplier, all flanges are welded to the two pipe segments. They are also welding the attachment points for the equipment and carrying out other preparatory work necessary for the installation of our CargoTube technologies. A pressure test was successfully completed. The tubes are now being conserved.

Equipment

The linear motor from Nevomo has arrived. We are very much looking forward to install our new propulsion system inside of goTube. Together with engineers from Nevomo we are going to test the system over summer with regard to all ist specifications!

Pavement and Equipment

There are next steps left and right! We would like to show you some more pictures from the construction site itself. Equipment is arriving and part by part it will be installed Now the pavement has been completed, so that one can already imagine where the Tube will be placed.

GoTube Design

We would like to introduce you to the technical drawings showing the installations we are working towards right now. Our GoTube demonstrator will be fully operational including vacuum pumps to reach operating conditions of CargoTube.

Foundations

We would like to show you the results of the last steps of the casting of our foundations. The three concrete pillars are now awaiting the tube to be placed on top.

Groundworks and Foundations

Fun fact the foundations of our test infrastructure are anchored 20m deep in the ground preventing any settling of the heavy infrastructure, allowing for precise measurements and accurate results. And no these are not our hyperloop tubes, they are way too small.

Take a look at the speed with which construction is going on.

Construction work in progress

After the pruning work in winter, the initial preparations for the foundation of our GoTube demonstrator have been completed and we are finally looking forward to further construction work this spring.